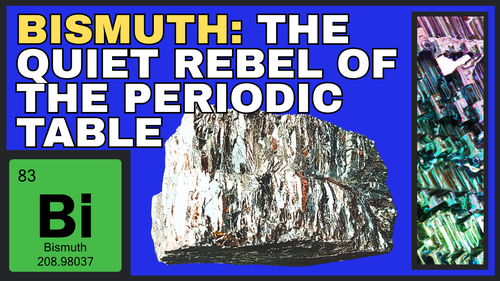

Bismuth: The Quiet Rebel of the Periodic Table

Bismuth has always lived in the margins of the metal world, a shimmering outsider with a personality too strange to ignore and too gentle to fit the stereotypes of heavy metals. For centuries, alchemists misidentified it as tin or lead, unable to reconcile its rainbow‑sheened crystals and low‑melting temperament with the brute force of the metals they knew. Today, Rotometals works with bismuth every day, and the more you handle it, the more you realize it’s a metal that refuses to behave like anything else in the shop. It melts at a temperature barely above boiling water, it expands when it solidifies, it forms geometric crystals that look like they were designed by a mathematician with a flair for neon, and it carries a density and heft that feels ancient, almost geological. Yet despite all that weight, bismuth is one of the most environmentally gentle metals we have, a paradox that has shaped its modern renaissance.

The story of bismuth begins in medieval Europe, where miners kept stumbling across a silvery metal that looked like lead but didn’t quite act like it. It melted too easily, cooled too strangely, and refused to tarnish the way lead did. Alchemists, always eager to categorize the world into neat symbolic boxes, couldn’t decide what to make of it. It wasn’t until the 1700s that chemists finally recognized bismuth as its own element, and even then, it remained a curiosity—useful in pigments, medicines, and low‑melting alloys, but never a star. What changed was the modern world’s appetite for safer materials. As industries began phasing out lead, bismuth stepped forward, quietly offering solutions no one expected. Rotometals saw this shift early, and today bismuth is one of the most versatile metals we supply, especially for customers who need performance without toxicity.

The science behind bismuth’s behavior reads like a list of contradictions. It’s dense, yet brittle. It’s heavy, yet non‑toxic. It’s a metal, yet it forms crystals that look like alien architecture. Its low melting point—just above 500°F—makes it ideal for casting, alloying, and experimentation. When you melt bismuth, it behaves like a calm pool of mercury‑colored liquid, and when it cools, it expands instead of shrinking. That expansion is the secret behind many of its modern uses. In precision casting, bismuth‑based alloys fill every microscopic detail of a mold. In safety devices, bismuth alloys melt predictably at specific temperatures, acting as thermal fuses. In ammunition, bismuth shot has become the go‑to alternative for waterfowl hunters who need the density of lead without the environmental impact. Rotometals has spent years refining bismuth shot production, and anyone who has worked with it knows the metal’s personality shows up even in the smallest pellets. It wants to crystallize, it wants to form facets, and it demands a careful balance of temperature, cooling rate, and handling to get the perfect spherical shot.

But the most iconic expression of bismuth is its crystal. When molten bismuth cools slowly, it forms stair‑step geometric structures called hopper crystals—hollow, angular, and iridescent. The colors aren’t dyes; they’re the result of a thin oxide layer that refracts light like oil on water. Every crystal is a miniature landscape, a metallic canyon system with neon edges. Artists love it. Scientists love it. Kids love it. There’s something almost meditative about watching the metal cool, waiting for the moment when the surface begins to wrinkle and the crystal skeleton emerges beneath. It’s a reminder that metals aren’t just industrial materials—they’re expressions of physics, chemistry, and time.

In industry, bismuth’s role continues to expand. It’s used in pharmaceuticals, cosmetics, fire‑safety systems, electrical fuses, specialty solders, and even advanced research into quantum materials. Its diamagnetic properties—meaning it repels magnetic fields—make it a favorite in scientific demonstrations. Its non‑toxicity makes it invaluable in applications where human contact is unavoidable. And its ability to form alloys with precise melting points has made it a cornerstone of low‑temperature casting and safety engineering. Rotometals has watched bismuth evolve from a niche curiosity into a modern workhorse, and the demand keeps growing as industries search for safer, smarter materials.

Yet for all its usefulness, bismuth still carries a sense of mystery. It’s the metal that doesn’t quite fit the mold, the one that behaves like it has its own agenda. It’s the metal that expands when it should contract, that forms rainbows when it should dull, that melts when you barely heat it, and that sits heavy in your hand while remaining one of the safest metals you can work with. In a world that often rewards conformity, bismuth stands out by being unapologetically itself. And that’s exactly why Rotometals loves it. It’s a reminder that the periodic table isn’t just a chart—it’s a collection of personalities, each with its own quirks, stories, and possibilities.

Bismuth is the quiet rebel of the metal world, a shimmering contradiction that has found its moment in the spotlight. Whether you’re casting shot, growing crystals, experimenting with alloys, or exploring safer alternatives to traditional materials, bismuth offers a blend of beauty, science, and practicality that few metals can match. And as industries continue to evolve, Rotometals will be right there, supplying the ingots, refining the alloys, and helping makers, artists, and engineers unlock everything this remarkable metal has to offer.

Recent Posts

-

Bismuth: The Quiet Rebel of the Periodic Table

Bismuth has always lived in the margins of the metal world, a shimmering outsider with a personality …Feb 10th 2026 -

Field’s Metal: From Scientific Oddity to Essential Low‑Temp Workhorse

Every alloy has a personality, and Field’s Metal has always been the quiet rebel of the metals world …Feb 4th 2026 -

The Tin Boom: What Sparked the Sudden Price Jump?

Tin’s sudden price surge has been driven by a collision of tight supply, aggressive investor activit …Jan 22nd 2026